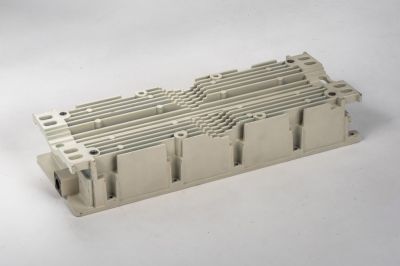

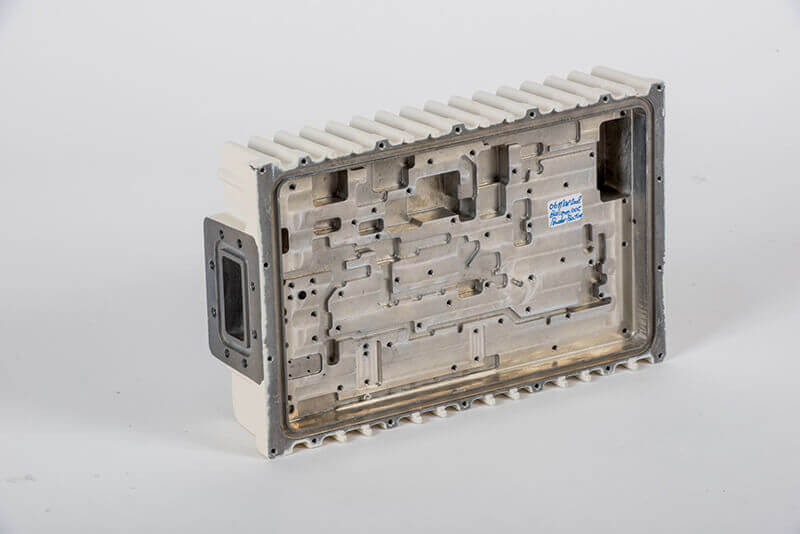

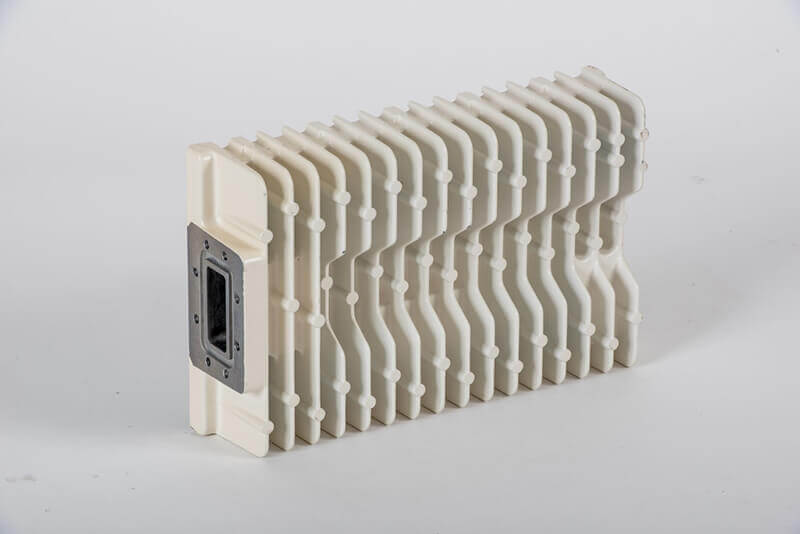

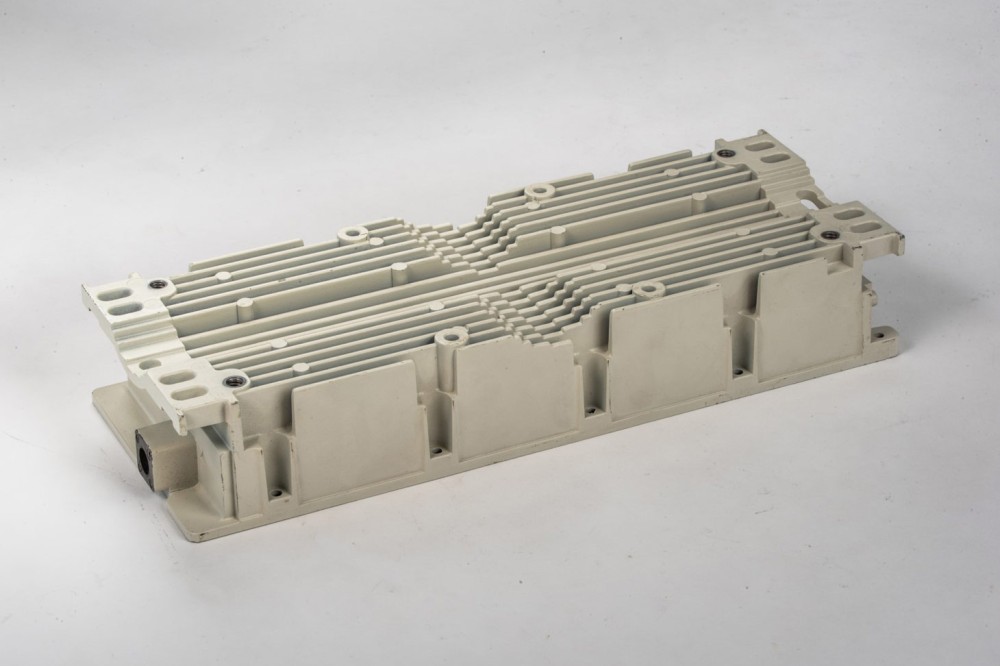

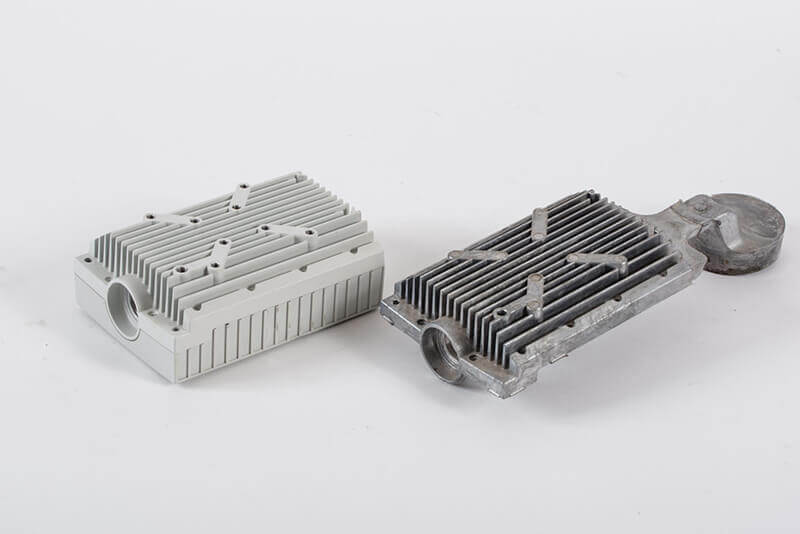

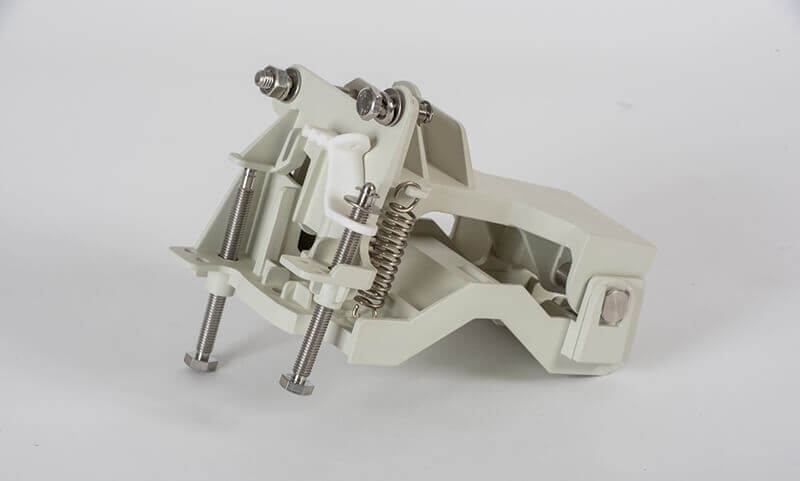

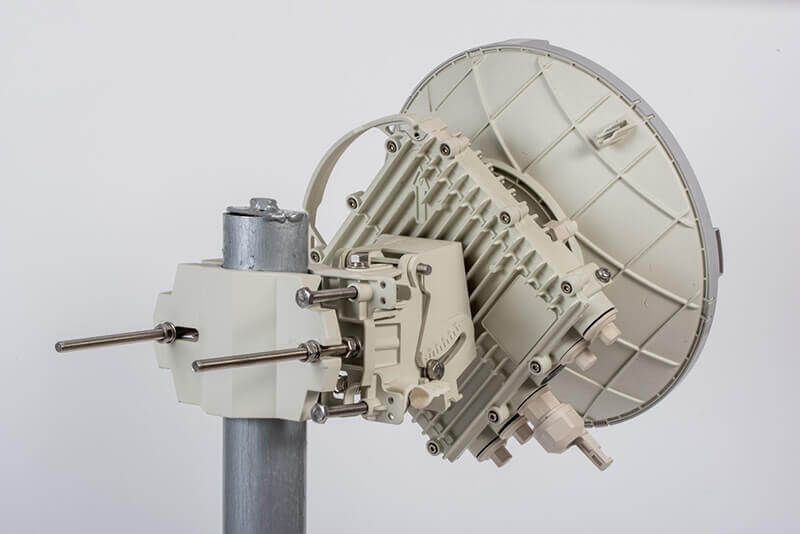

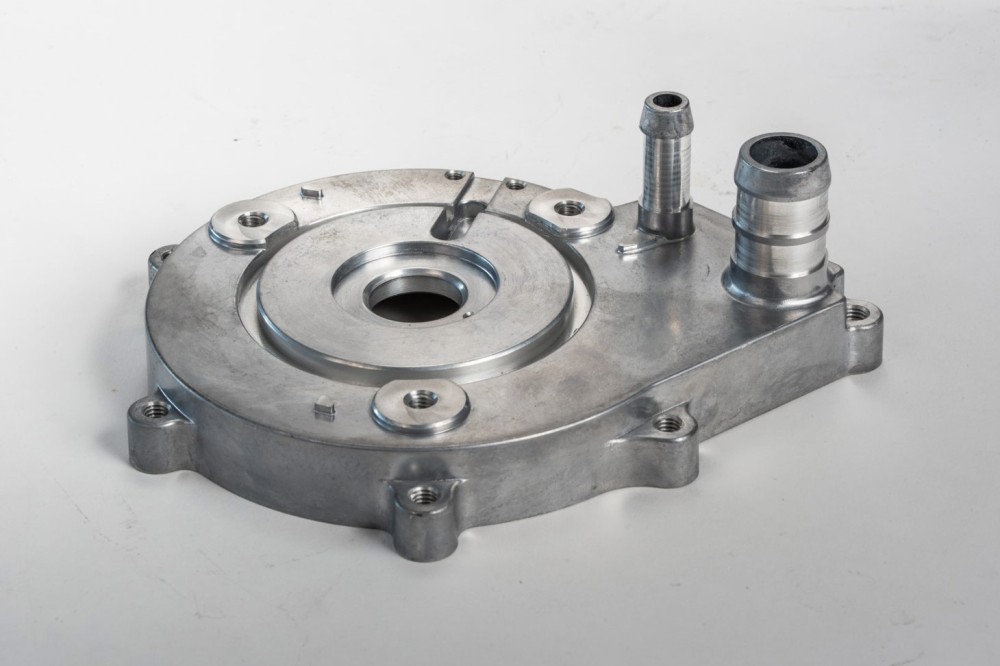

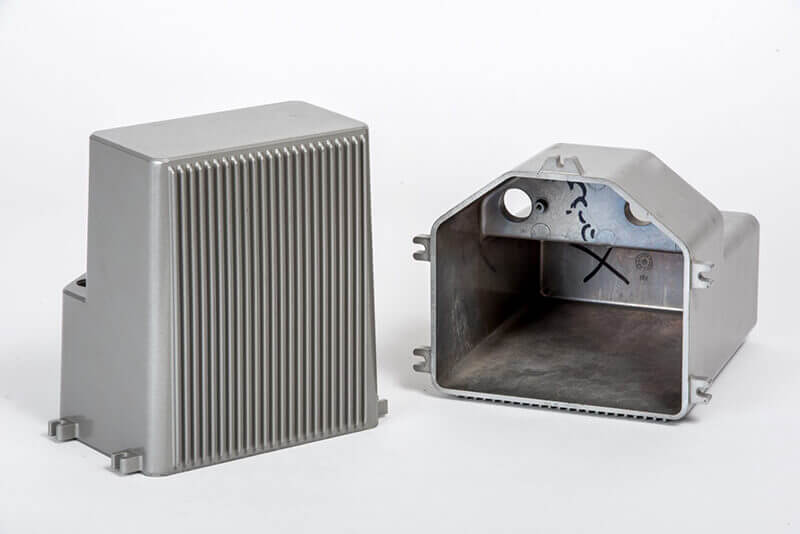

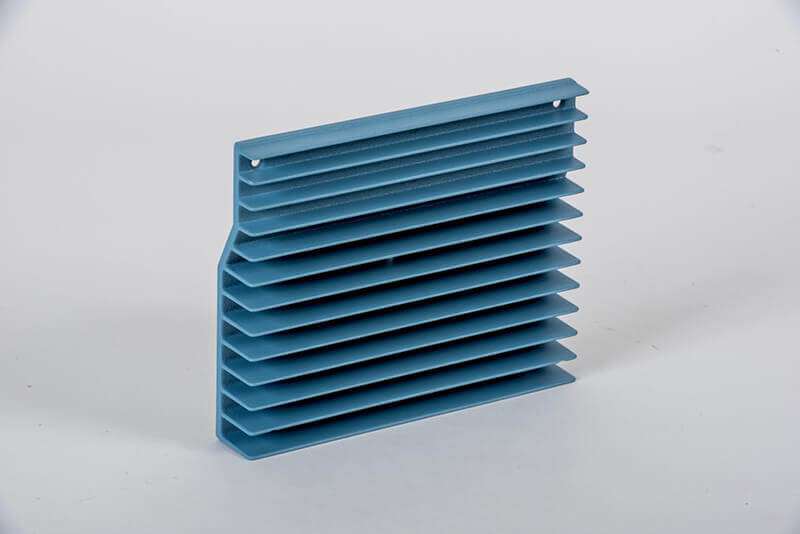

Aluminum die casting

Metalitec offers high quality aluminum castings in fine materials according to strict injection standards.

Aluminum is the most common raw material used in pressure castings.

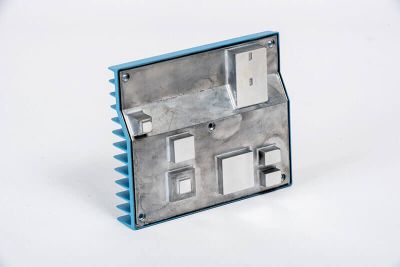

It offers several advantages such as strength, stiffness, corrosion resistance, thermal conductivity and high temperature resistance.

Aluminum is used in a wide range of products in the fields of communication, infrastructure, optics, medicine and lighting.

With years of skill in aluminum casting, Metalitec strives to advise and share its vast experience.

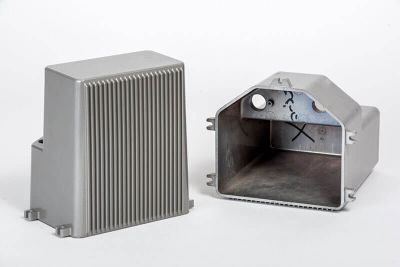

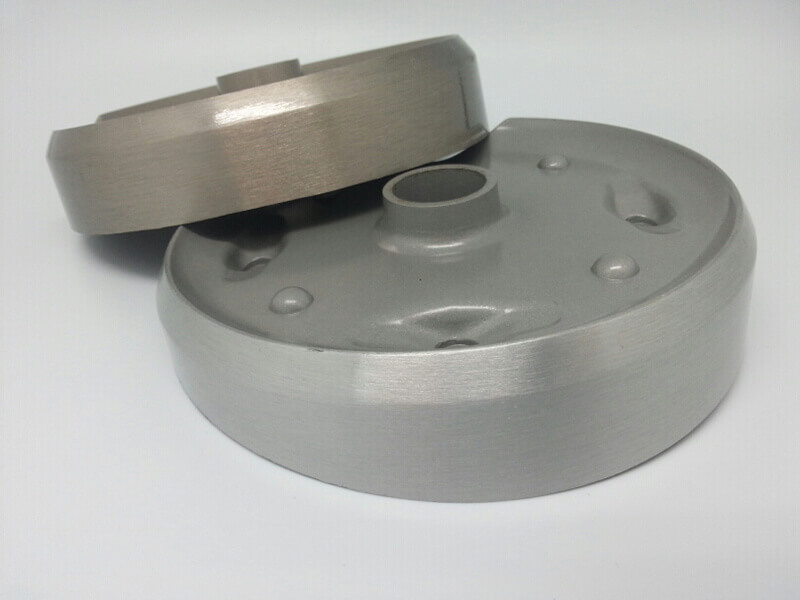

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity.

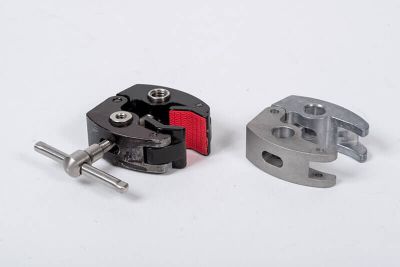

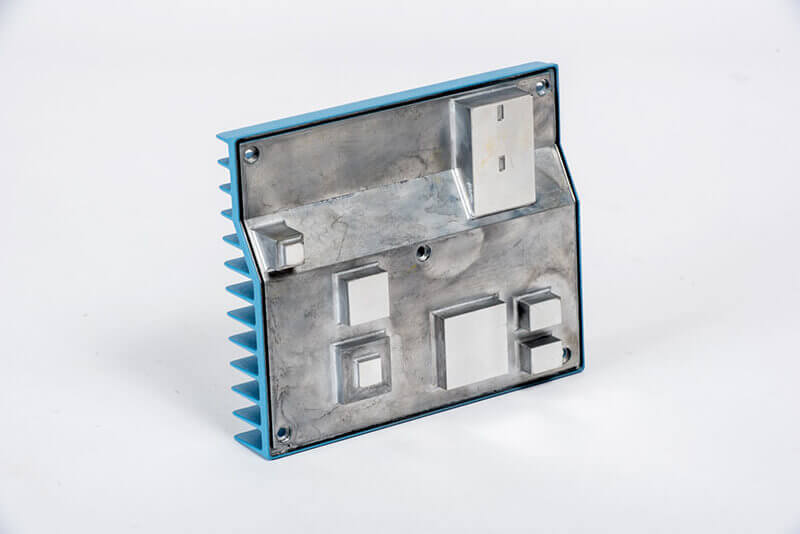

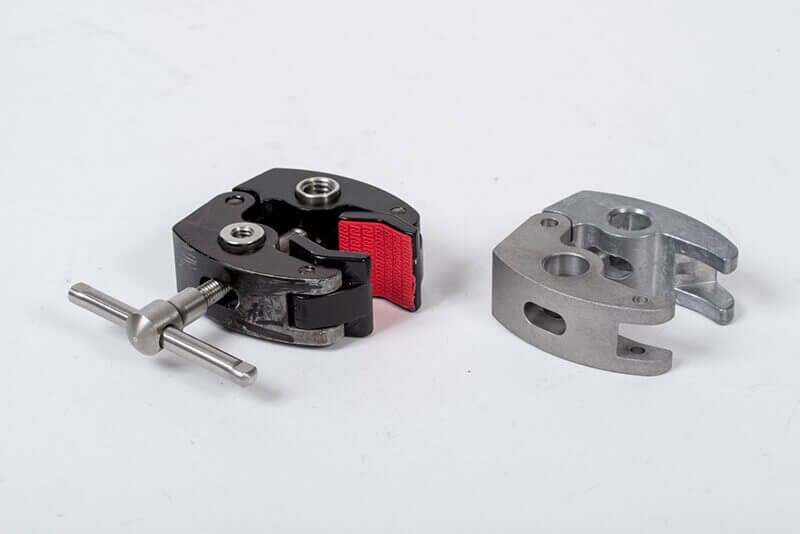

The parts are made mostly of non-ferrous metals, including zinc, magnesium and aluminum. Production through pressure casting enables a significant reduction in cost per unit, when required to produce medium size series for complex metal products, as an alternative to manufacturing via CNC machines and accurate metalworking.

The process of production using pressure castings is a relatively simple process and enables effective mass production while optimizing the price per unit.

Metalitec offers its customers a wide variety of die casting production services including surface finishing for high-quality look, surface treatment, cleaning and removal of remnants, threading, painting, polishing and coatings.