Aluminum Extrusion

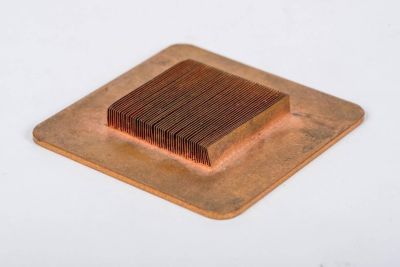

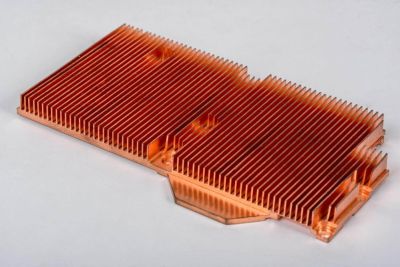

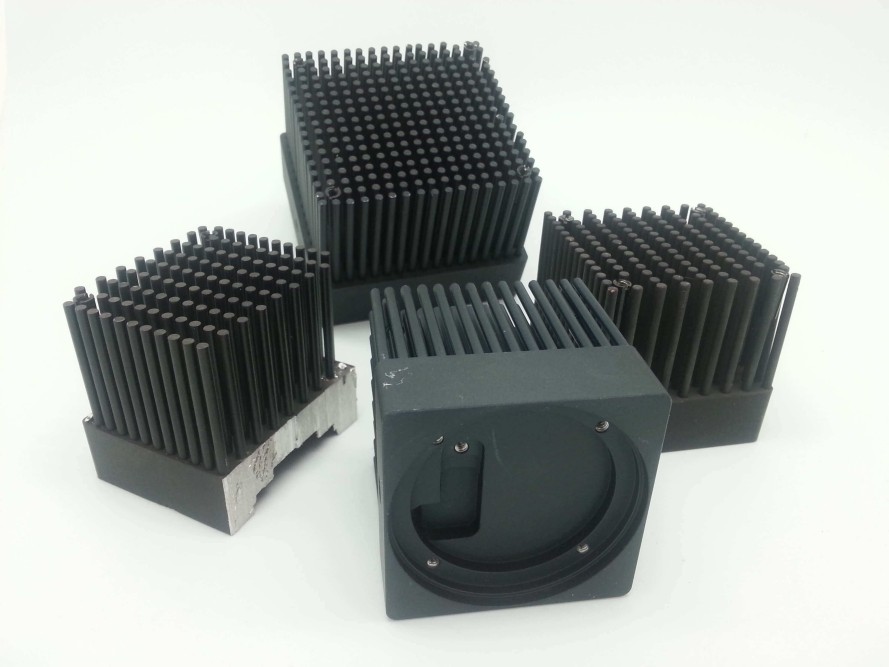

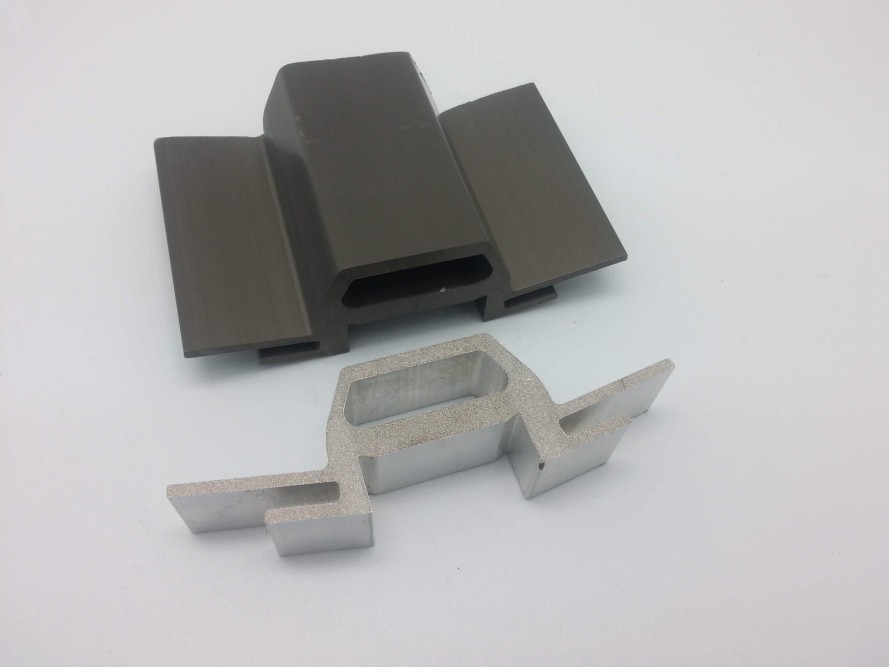

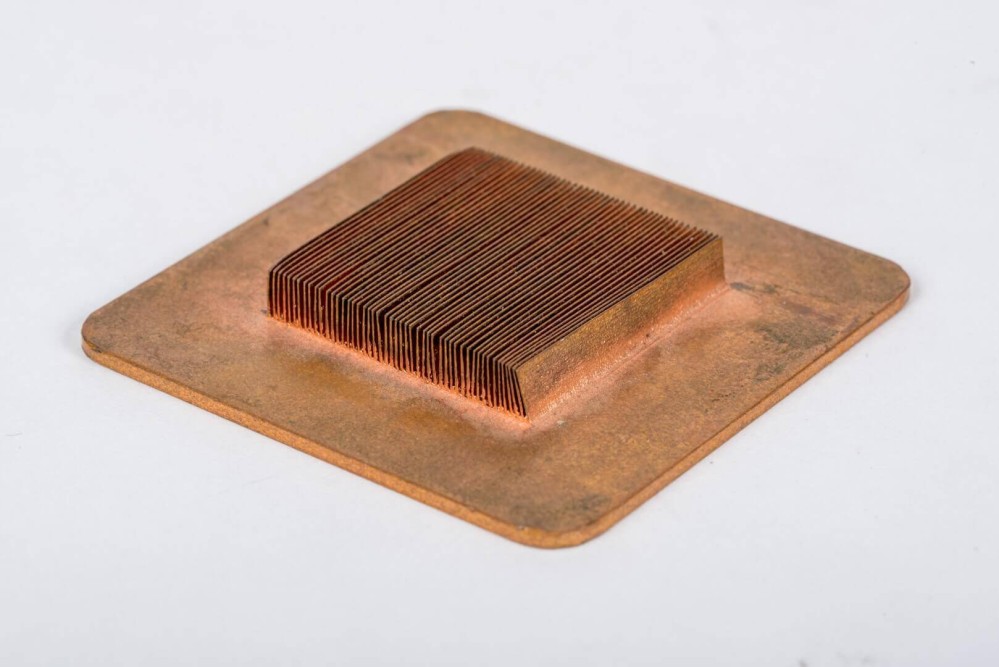

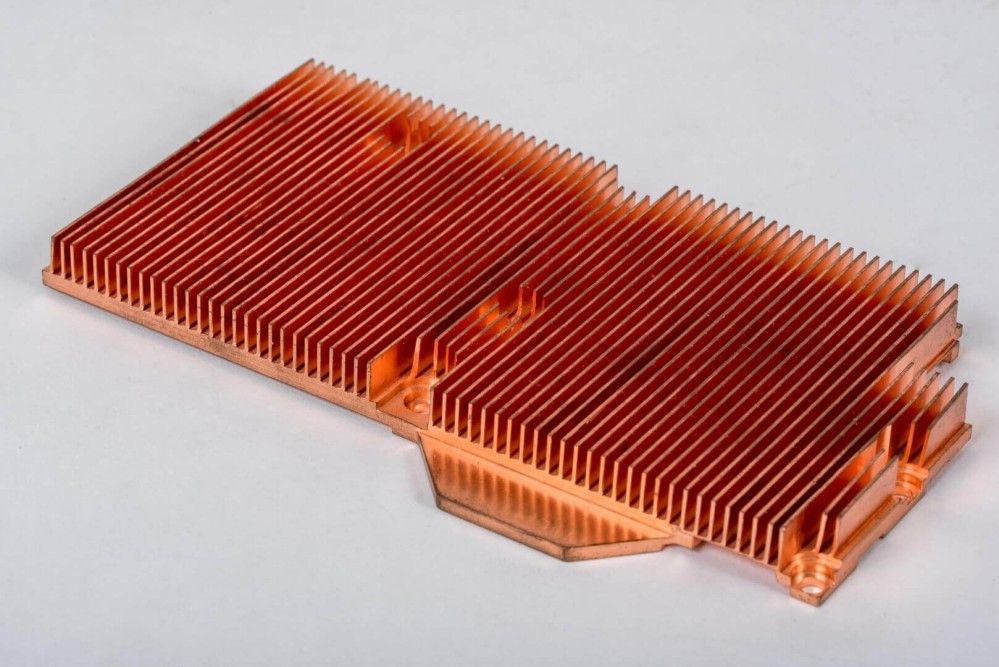

Metalitec provides extrusion services, applying aluminum profiles for the production of electronic cooling applications, including painting, finishing, and coating services for both profiles and finished products.

Metalitec produces all standard and custom aluminum extrusion alloys including aluminum profiles for heat sinks, along with painting, coating and finishing services for the profiles and finished products.

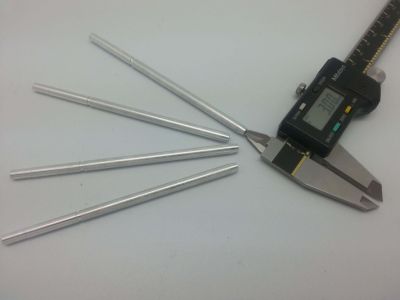

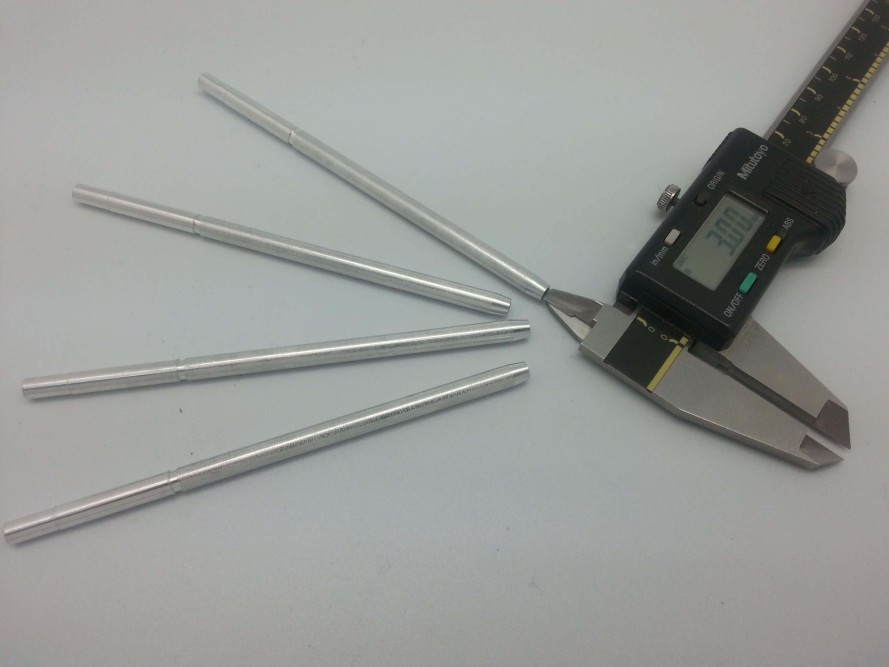

The aluminum extrusion process forms aluminum by heating it and forcing it through a shaped opening in a die. The production of the extruded profiles is a multi-step process that enables custom profiles of up to 4000 tons.

Our team of experts provide advice and support for custom extrusion design and manufacturing. We offer unique design templates that enable us to utilize profiles for various applications, including heat sinks, cooling devices for electronic systems and more.

The profile extrusion process along with finishing services, such as machining, profile bending, precision cutting, liquid painting and powder coating undergo strict quality assurance and control throughout the process and are integrated into our quality control ERP system, complying with the ISO 9001:2000 standard.