Electronic Packaging

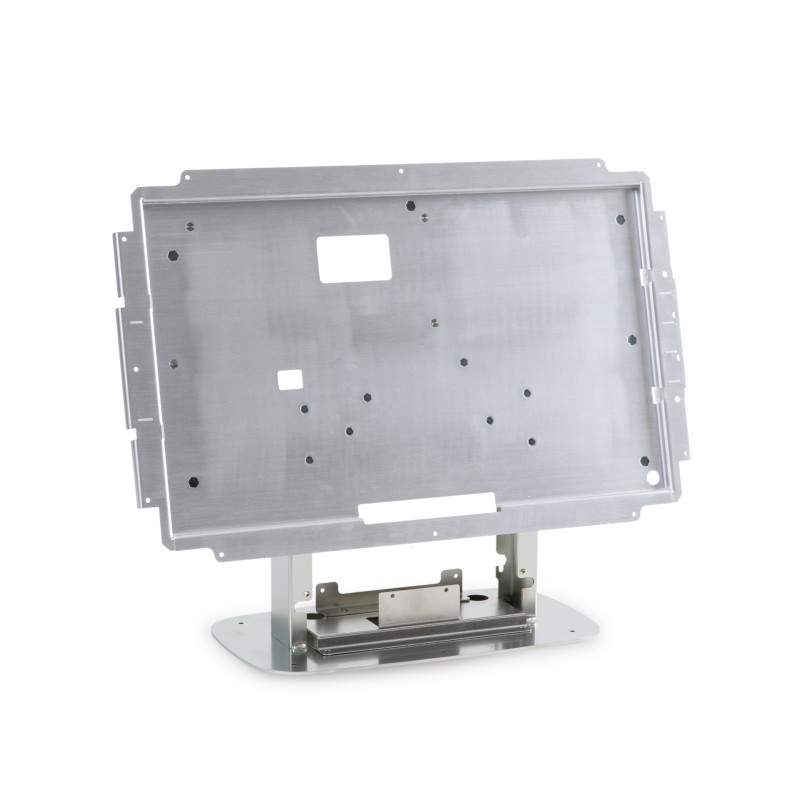

Communications, computer and technology companies are the main consumers of Metalitec’s electronic packaging services.

Our services include engineering design and 3D simulations, computerized metal bending and finishing processes.

Production services and electronic packaging

We provide our customers with comprehensive services in the field of electronic packaging, including engineering design, optimization of planning, selection of the production technologies, improvement of prototype costs and finally mass production.

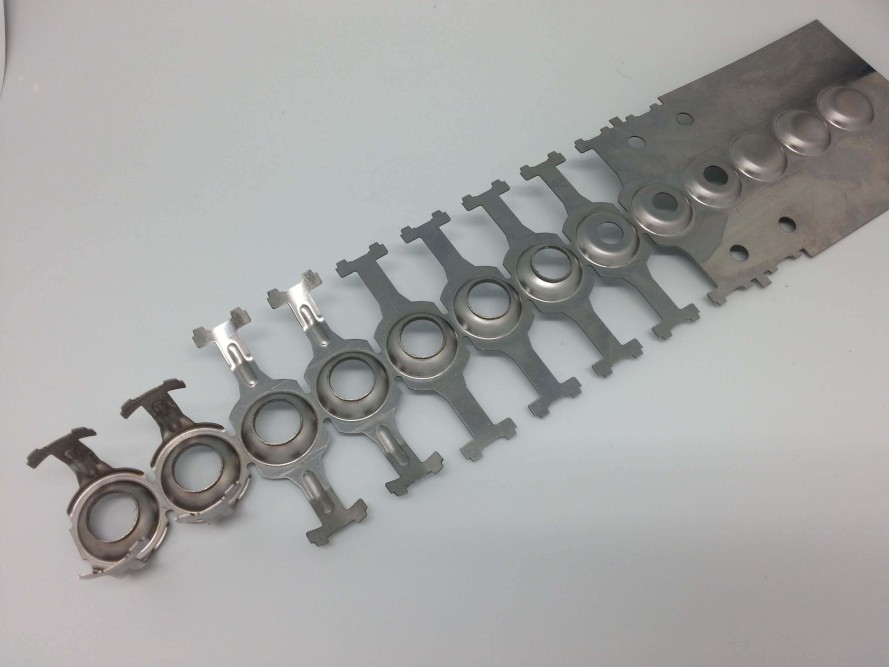

Production technology in electronic packaging - punching and bending

Metalitec’s manufacturing technologies include CNC punching machines (produced by AMADA of Japan and TRUMPF of Germany - renowned leaders in this field) that enable punching in metal thicknesses of up to 8 mm.

Our bending system consists of computerized machines that enable complex bending to an endless range of geometries with highest levels of accuracy.

Finishing processes in electronic packaging

In products that require assembly and reinforcement, our production system enables spot, argon and carbon dioxide welding.

Special finishing product services include polishing, stud insertion, sub-assemblies, full assembly, painting, wet painting and powder coating.

Computerized design

Our staff of engineers provide consulting and support from the early design stages of the product and throughout the manufacturing process. Using advanced computer software – SolidWorks and Pro-E, which provide 3D visualization, we assist in maximizing production planning and efficiency prior to electronic packaging and assembly.