CNC machining & Turning

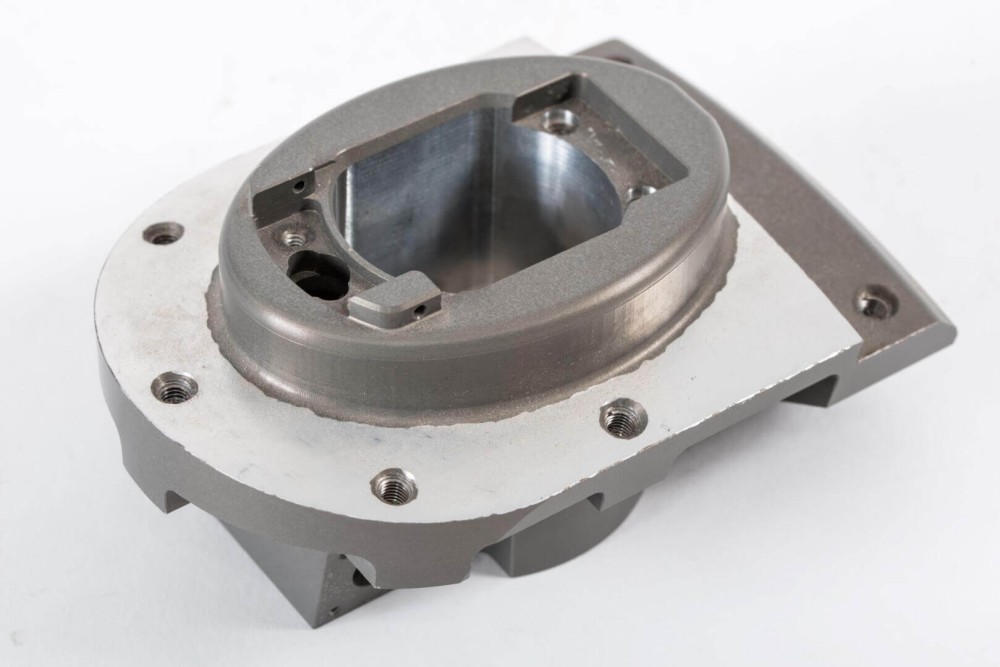

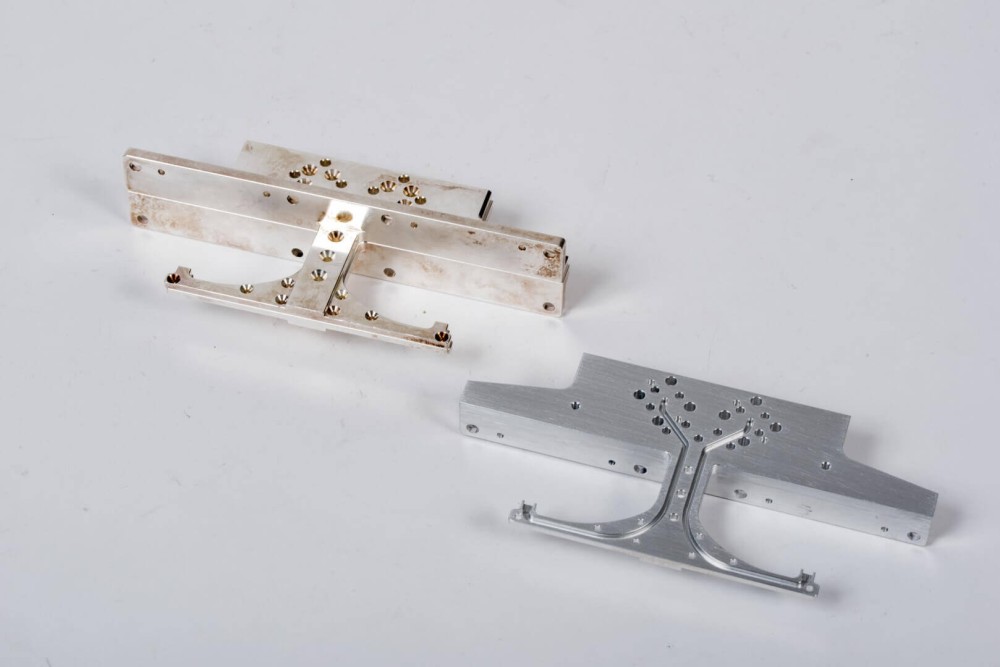

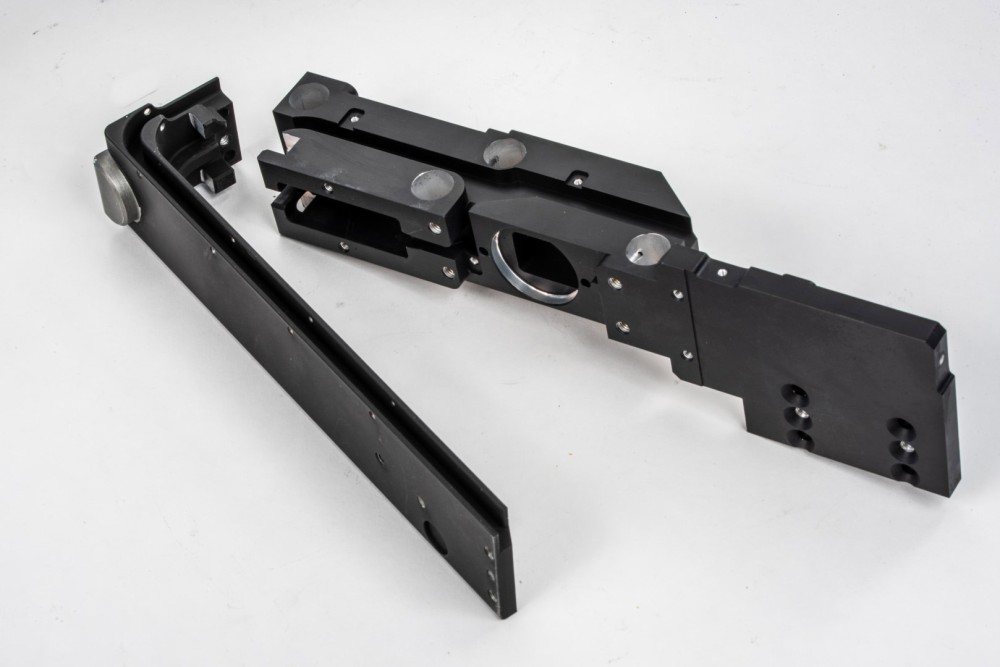

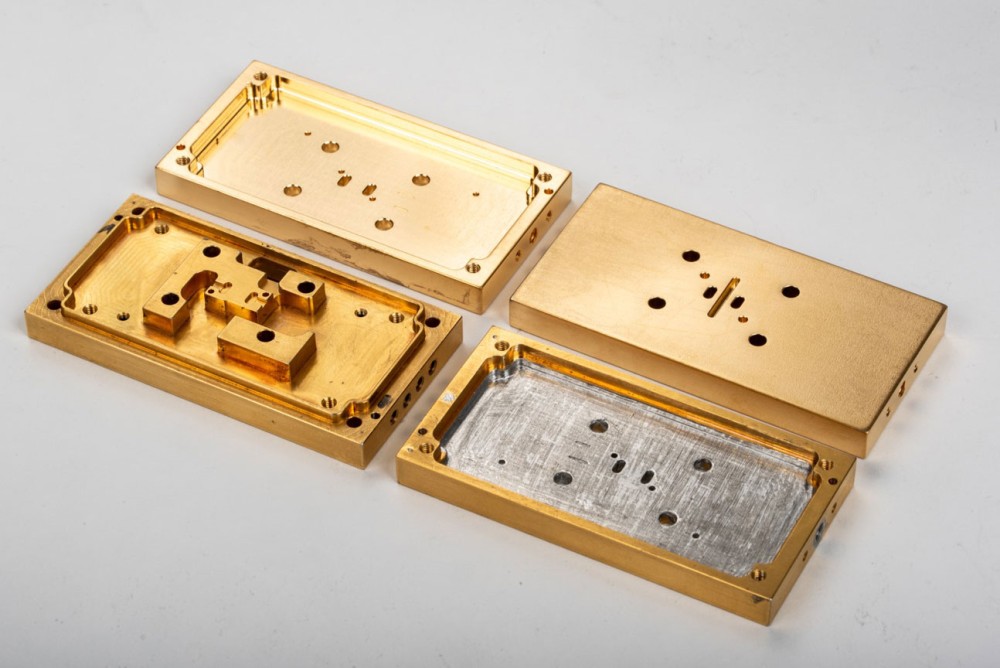

Metalitec specializes in the production of parts and components utilizing plastic and metal raw materials, machining with the latest technologies and equipment to provide excellent finishing precision.

Milling in action

This video shows a milling machine. The Spindle rotates in high RPM, moves on all axes of space and removes/milling material from the object. The movement of the milling machine is controlled by a computer into which a 3D model is fed. This machine can also replace spindles (drills) automatically, to remove material/chips of different sizes.

Metal processing via precise machining is an industry that serves most of the manufacturing companies in Israel and abroad.

Machining - In which Industries?

Our major customers include manufacturing plants, electronic industries, optics, irrigation, automotive, medical and others.

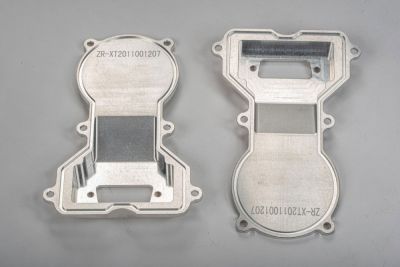

The use of precision machining technology is particularly common in the production of complex, small and precise parts and components, mainly serving customers' needs in the manufacturing of small series, prototypes and medium-sized series, as a preliminary stage for mold production.

Machining with Metalitec

Matalitec provides precision machining services utilizing the latest technologies and equipment, operated by a professional, highly experienced team. Our services ensure timely, ongoing supply and production of small and large series with excellent finishing and precision.

Among our unique capabilities is the possibility of processing tempered materials, turning in very small diameters (starting at 0.35 mm) and drilling procedures to a minimal diameter of 0.25 mm.

Our quality assurance and manufacturing procedures are conducted via an internal ERP system, which enables ongoing monitoring of each process and stage of production and compliance with ISO 9001: 2000 standards.

Professional engineering teams perform regular quality inspections to confirm product quality and compliance with customer’s specifications. We provide certifications of the raw materials used and quality assurance reports re operations and finishing, as required.

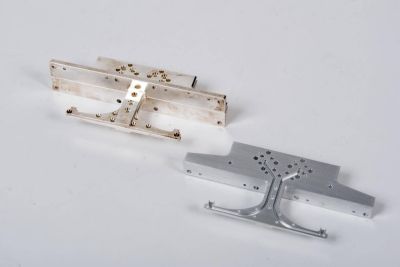

We bring expertise in the production and machining of components made of raw materials that include plastics, metals, various alloys of stainless steel, copper alloys, aluminum alloys and plastic raw materials such as delrin, oclone, nylon and Teflon.

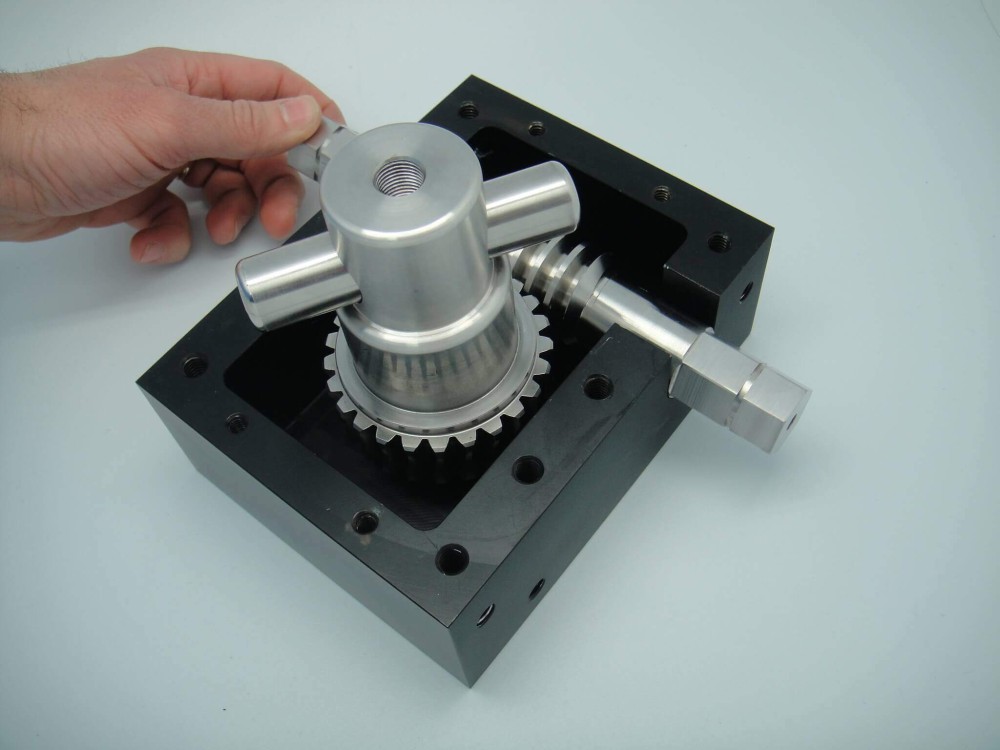

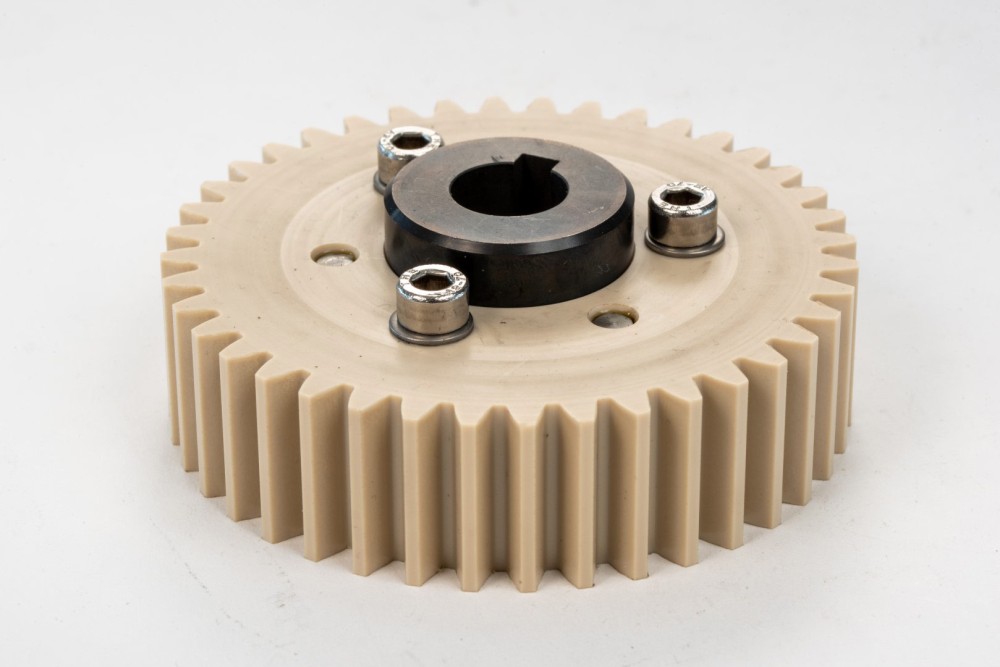

Gear Hobbing process

Hobbing is a machining process for gear production and cutting. During the process, the teeth of the gear are progressively cut into the material by a series of cuts made by the hob.

Hobbing is a relatively common and inexpensive method for producing gears and sprockets.

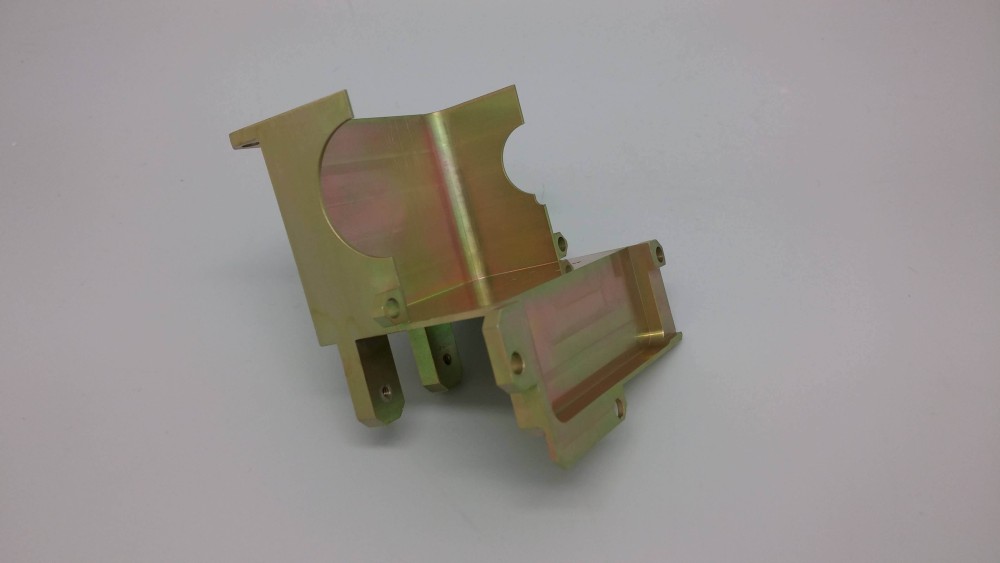

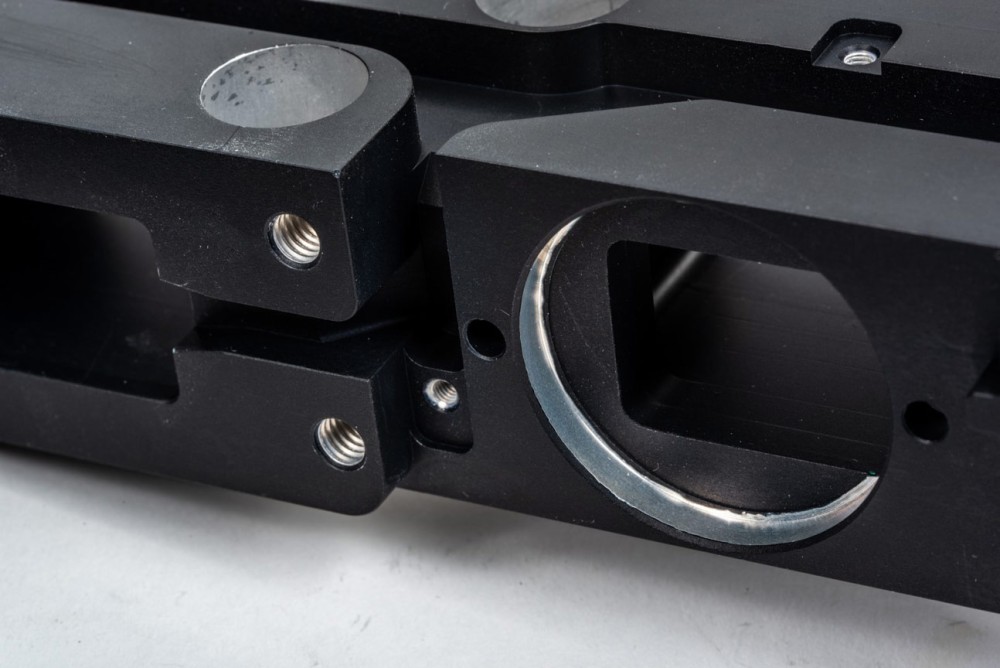

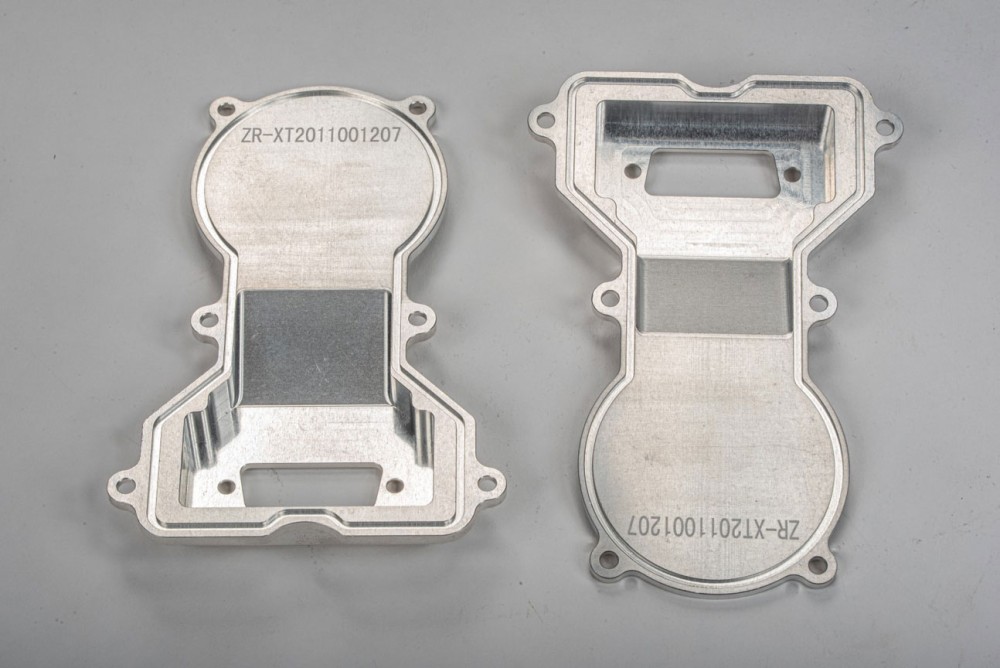

Broaching process

Broaching is one of the most precise and efficient processes in the metalworking area.

Broaching is a machining operation which uses a tool called a broach, which moves over the workpiece to remove material, cutting a predetermined shape.

Odd shapes, circular for example, are obtained by broaching.